|

Clamp On Ultrasonic Flow Meter Parameters |

||

|

Host |

Principle |

Clamp On Ultrasonic Flow Meter |

|

Accuracy |

±1% |

|

|

Signal Output |

1 way 4~20mA output, electric resistance 0~ 1K, accuracy 0. 1%(optional) |

|

|

Display |

2X20 character LCD with backlight, support the language of Chinese, English and Italy |

|

|

Signal Input |

3 way 4~20mA input, accuracy 0. 1%, acquisition signal such as temperature, press and liquid level |

|

|

Connect the temperature transducer Pt100, can finish the heat/energy measurement |

||

|

Data Interface |

Insulate Rs485 serial interface, upgrade the flowmeter software by computer, support the MODBUS |

|

|

Special Cable |

Twisted-pair cable, generally, the length under 50 meters ; Select the RS485, transmission distance can over 1000m |

|

|

Pipe Installation Condition |

Pipe Material |

Steel, Stainless steel, Cast iron, Copper, Cement pipe, PVC, Aluminum, Glass steel product, liner is allowed |

|

Pipe Diameter |

DN32~6000mm |

|

|

Straight Pipe |

Transducer installation should be satisfied: upstream10D, downstream 5D, 30D from the pump |

|

|

Measuring Medium |

Medium |

water,sea water ,alcohol,Acid and alkali,waste water,beer,all kinds of oil Single liquid can transmit sound wave. |

|

Temperature |

-30~160℃ |

|

|

Turbidity |

No more than 10000ppm and less bubble |

|

|

Flowrate |

0~±7m/s,Forward and backward measurement |

|

|

Work environment |

Protection grade |

Host:IP67;flow sensor:IP68 |

|

Temperature |

Host:-20~60℃;flow sensor:-30~ 160℃ |

|

|

Humidity |

Host: 85%RH; Flow sensor:can measure under water, water depth^2m (tansducer sealed glue) |

|

|

Power Supply |

DC8~36V or AC85~264V |

|

|

Power Consumption |

1.5W |

|

|

Dimension |

132*150*85mm(host) |

|

Installation

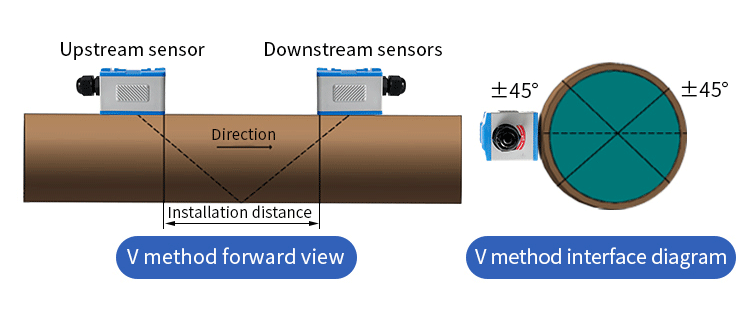

V method: compared with the standard installation method, easy to useaccurate measurement, when the installation oftwo sensors level alignment,the center line and the pipeline axis level can be measured pipe diameter ofabout DN15-DN40mm.

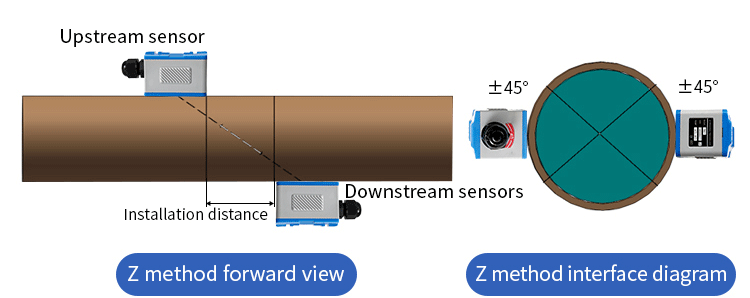

Z method: commonly used installation method, characterized by directultrasonic transmission in the pipeline, no reflection(called single soundpath), the signal attenuation loss is small. The measurable diameter range isDN50-DN6000mm.The actual installation, it is recommended that more than200mm pipe to choose the Z method.